Waves Explained: tidal bores. Understand the science behind the world’s most legendary waves. AllWaves explains how it works.

Waves Explained: tidal bores. Understand the science behind the world’s most legendary waves. AllWaves explains how it works.

Waves Explained: tidal bores. Understand the science behind the world’s most legendary waves. AllWaves explains how it works.

We are excited to introduce one of our key features: the creation of perfect beginner waves designed to enhance the first surfing experience for novices.

We are excited to introduce one of our key features: the creation of perfect beginner waves designed to enhance the first surfing experience for novices.

A testimonial by a stoked surfer on foiling in the AllWaves wave pool.

Surfing the wavepool on foil in the AllWaves R&D center in Knokke-Heist, Belgium was such a unique experience! I believe it’s the first time a foiler has ever surfed a wave pool and it exceeded all expectations.

In other wavepools it would be too shallow or not spacious enough, but the AllWaves technology generated waves which are perfect for foiling!

You paddle out to the middle of the lake and instantly get that ocean feel. There is no other structure or concrete walls around you. The waves start coming at you just like regular swell does, amazing!

In our session we were testing the ‘Waikiki’ setting. It’s a smaller wave than what we have seen before. The wave perfectly peels left and right, just like an A-frame wave does. As a foiler, you don’t need much more. From the first take-off, it felt exactly like surfing a clean two foot offshore day out at sea. Pumping back out, you see multiple waves being generated and you can timely choose the one that suits your speed. In the current testing facility, we were able to make two to three turns before pumping back out again and catching another wave.

Remarkable is the amount of waves generated in one sequence, an astounding 40 waves which all keep the same quality. The waves seem never ending and we weren’t able to catch all the waves in one sequence, our cardio didn’t allow. The amount of turbulence is minimal and the lake in general does not get affected by any backwash.

Looks like foiling has a future in wave pools! Who would have thought?

Testimonial by Tom Soupart, Belgian champion foil surfing.

Keep surfing!

What happens behind the scenes in wave pool product development? Testing, testing and some more testing. Testing plays a crucial role in the development of any new technology. At AllWaves, we simulate real-world conditions in a controlled environment to validate the performance, reliability and safety of our wave pool designs before investing significant more resources into full-scale production.

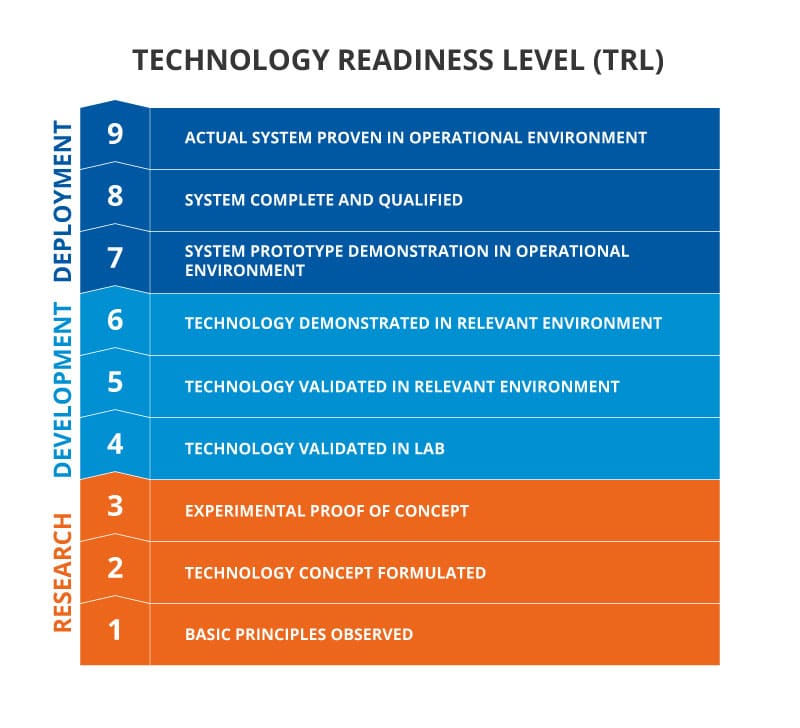

One framework we use is the NASA Technology Readiness Level (TRL) scale. The TRL scale is a measurement system developed by NASA. It is used to assess the maturity of a particular technology, ranging from basic research (TRL 1) to system test, launch, and operations (TRL 9).

Here are the different NASA TRL phases broken down:

TRL 2-4: During these early stages, scale models are used to demonstrate the basic principles of a technology and validate its functionality in a laboratory setting. This includes building proof-of-concept prototypes and testing them under controlled conditions to gather reliable data and benchmark performance. All of this happens in scale models. We built & developed multiple wave pool scale models in this phase, 1:20 scale, and 1:10 scale in our test site in Ostend, Belgium.

TRL 5-6: As technology matures, scale models are used to validate the system in a relevant environment, such as a simulated operational setting. This helps identify and address potential issues before moving to full-scale testing. We tested all critical components in an indoor wave pool scale 1:4 prior to building our full-scale test pool.

TRL 7-8: In the final stages of development, a full-scale model is used to demonstrate the system in an operational environment, such as a field test or pilot plant. In our case, this is the R&D test wave pool in Knokke-Heist. This ensures the technology meets all performance requirements and is ready for commercial deployment. This is how potential surf park developers can assess the technology for the projects they have in their countries.

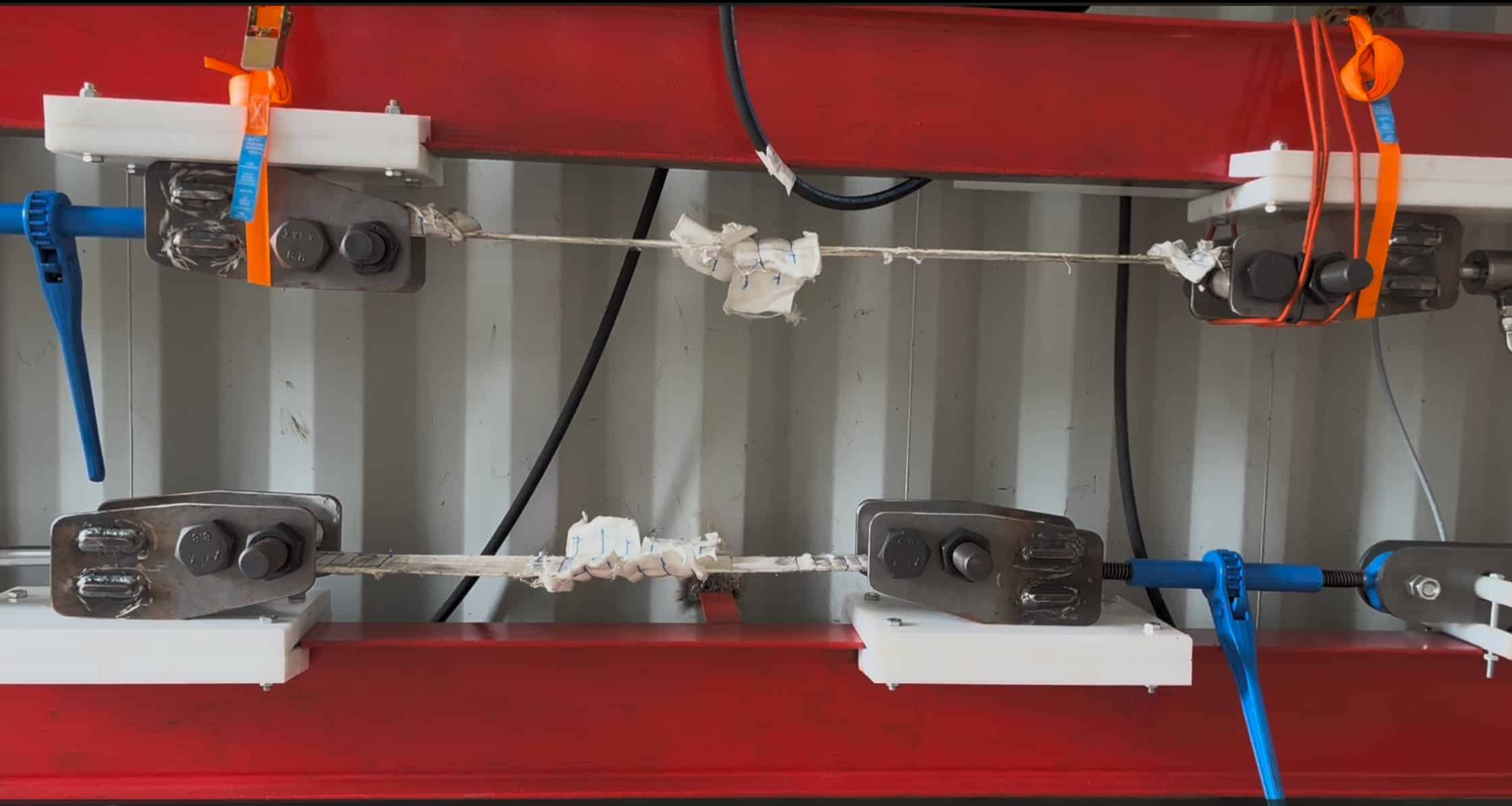

Throughout these different TRL phases, test rigs are commonly used. In our case, this is a tool that simulates the same forces applied on the hydraulics & textile of our wavemaker when making waves. In our test rigs we research various designs & combinations of high-performance fabrics, confection methods & interfaces with our hydraulic equipment. Which has a lot of benefits in wave pool product development.

CFD or computational fluid dynamics is a term you also often hear in the world of water systems & wave pools. Although it has it benefits, nothing beats a real-world scale model or a full scale prototype to actually simulate water movement & forces. The computer-based model is only as powerful as the data used to feed & calibrate it.

In conclusion, the use of the NASA TRL framework in conjunction with test rigs, is essential for the successful development of new technologies, products, and systems. At AllWaves, we use both. Thereby we improve product quality, reduce development costs, enhance reliability, accelerate integration, and shorten our time-to-market.

To learn more about our wave pool product development, read further on our blog or follow us on social media.

Keep surfing!

Can wave pools match or even surpass traditional ocean surf sites for the Olympics? Wave pools can create consistent, predictable waves.

AllWaves, a pioneering company in wavepool technology, has unveiled its innovative technology by means of a demonstration by international surfers.

Waves Explained: Nazaré. Understand the science behind the world’s most legendary waves. AllWaves explains how it works.