What happens behind the scenes in wave pool product development? Testing, testing and some more testing. Testing plays a crucial role in the development of any new technology. At AllWaves, we simulate real-world conditions in a controlled environment to validate the performance, reliability and safety of our wave pool designs before investing significant more resources into full-scale production.

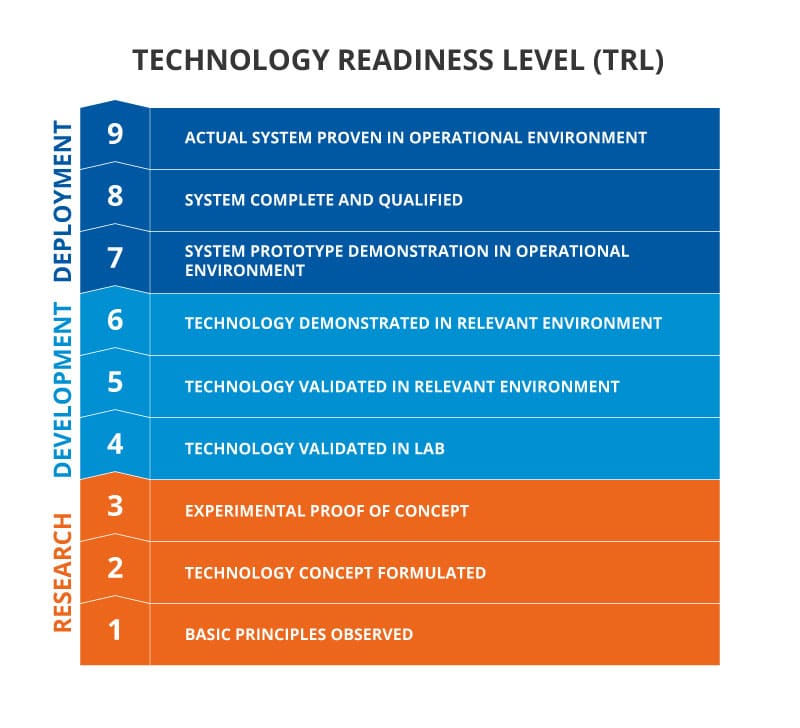

One framework we use is the NASA Technology Readiness Level (TRL) scale. The TRL scale is a measurement system developed by NASA. It is used to assess the maturity of a particular technology, ranging from basic research (TRL 1) to system test, launch, and operations (TRL 9).

What are the NASA TRL Phases

Here are the different NASA TRL phases broken down:

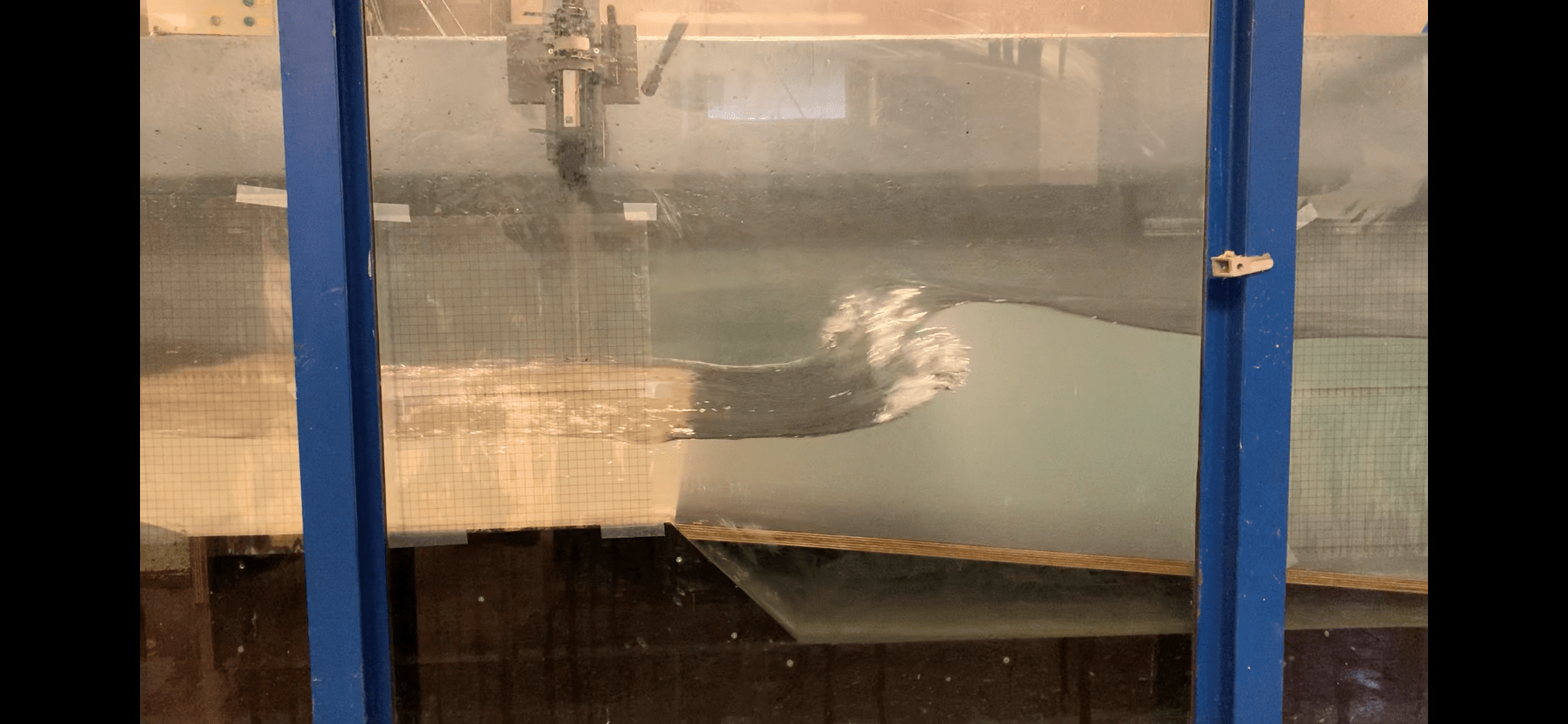

TRL 2-4: During these early stages, scale models are used to demonstrate the basic principles of a technology and validate its functionality in a laboratory setting. This includes building proof-of-concept prototypes and testing them under controlled conditions to gather reliable data and benchmark performance. All of this happens in scale models. We built & developed multiple wave pool scale models in this phase, 1:20 scale, and 1:10 scale in our test site in Ostend, Belgium.

TRL 5-6: As technology matures, scale models are used to validate the system in a relevant environment, such as a simulated operational setting. This helps identify and address potential issues before moving to full-scale testing. We tested all critical components in an indoor wave pool scale 1:4 prior to building our full-scale test pool.

TRL 7-8: In the final stages of development, a full-scale model is used to demonstrate the system in an operational environment, such as a field test or pilot plant. In our case, this is the R&D test wave pool in Knokke-Heist. This ensures the technology meets all performance requirements and is ready for commercial deployment. This is how potential surf park developers can assess the technology for the projects they have in their countries.

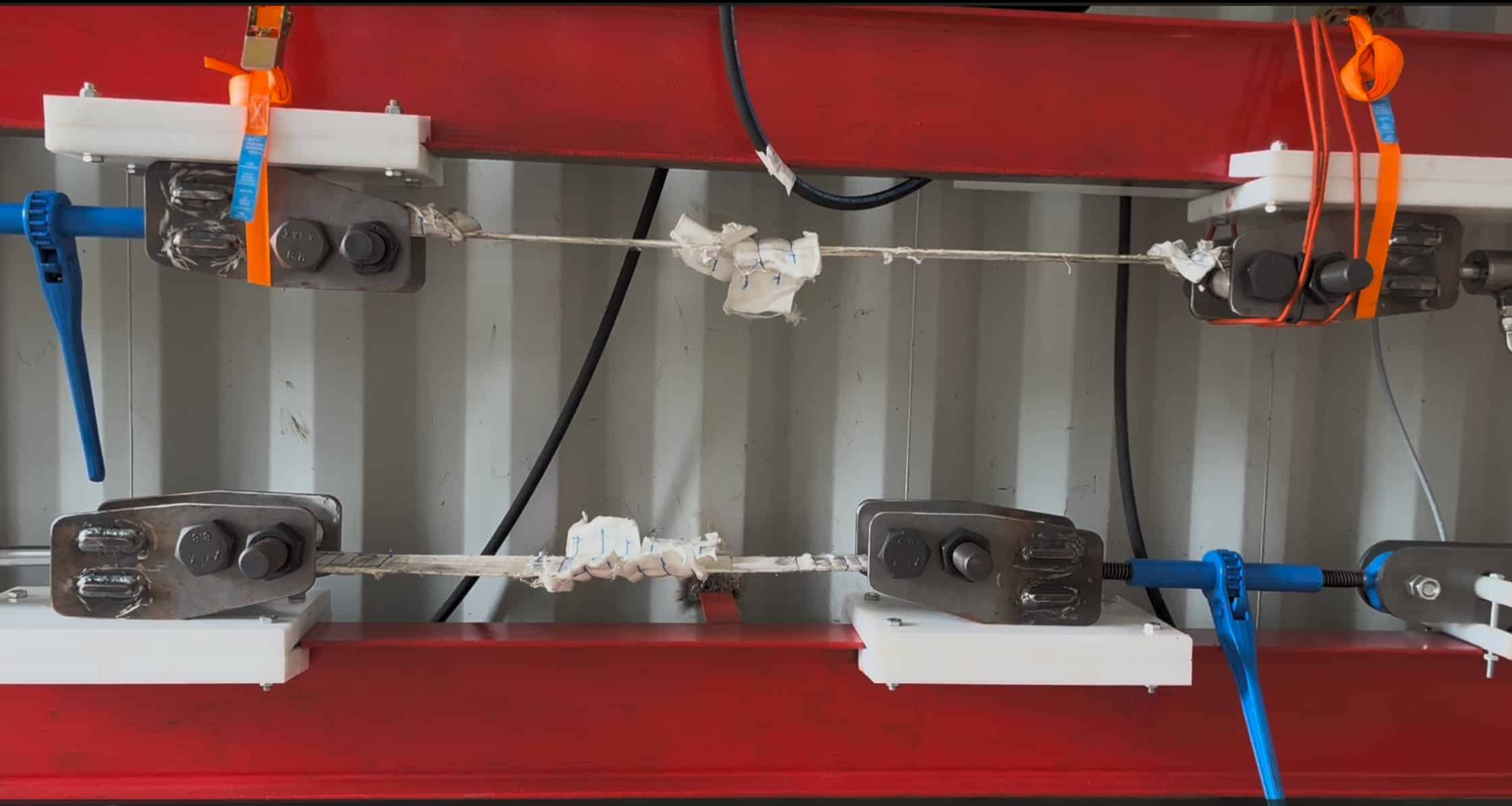

What are Test Rigs

Throughout these different TRL phases, test rigs are commonly used. In our case, this is a tool that simulates the same forces applied on the hydraulics & textile of our wavemaker when making waves. In our test rigs we research various designs & combinations of high-performance fabrics, confection methods & interfaces with our hydraulic equipment. Which has a lot of benefits in wave pool product development.

Benefits of Using Test Rigs

- Improved product quality: By thoroughly testing components and systems under controlled conditions, test rigs help identify and address potential issues early in the development process, leading to higher-quality products.

- Reduced development costs: Test rigs allow for rapid prototyping and iterative testing, which can significantly reduce the time and resources required to bring a new product to market. By using test rigs, we can simulate what happens in an operational environment after, for example, 1 year of making waves and millions of cycles. And we can see those results in only a matter of weeks.

- Enhanced reliability: By pushing systems to their limits in a safe and controlled environment, test rigs help ensure that products will perform reliably under real-world conditions. To pass our tests, the design needs to perform several millions of cycles and several tons of load.

- Accelerated integration: Test rigs facilitate early integration with other parts of the system, such as software, allowing for a more seamless development process.

- Increased sales: By demonstrating the quality, reliability, and performance of their products, companies can increase customer confidence and drive sales.

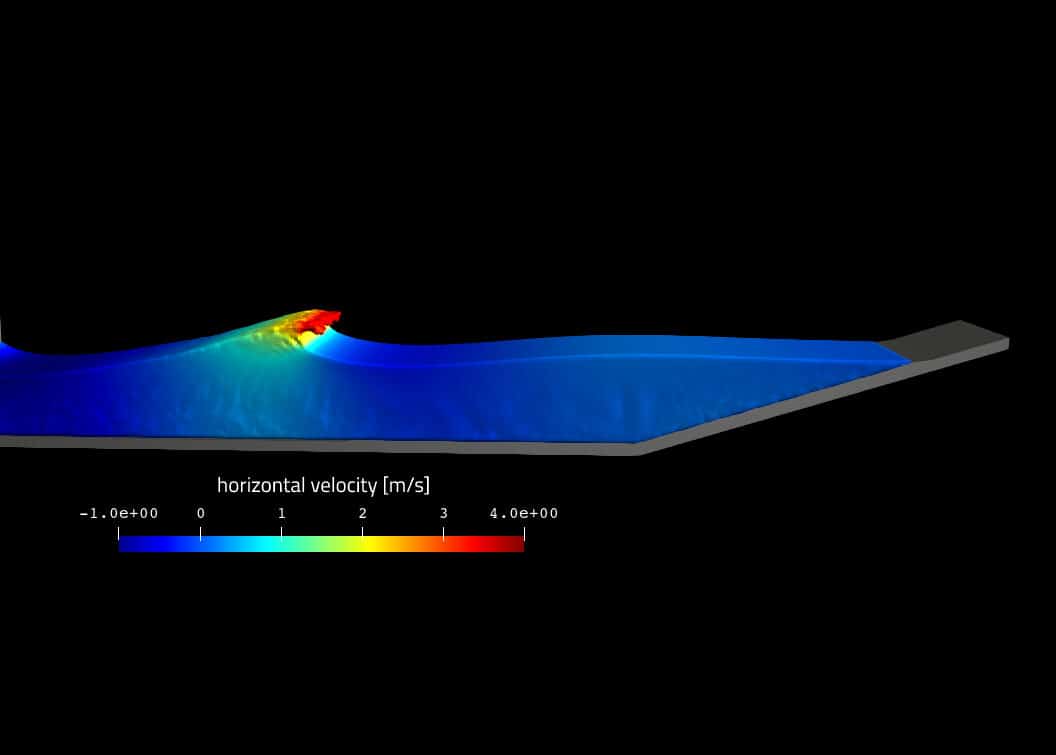

What is “CFD”

CFD or computational fluid dynamics is a term you also often hear in the world of water systems & wave pools. Although it has it benefits, nothing beats a real-world scale model or a full scale prototype to actually simulate water movement & forces. The computer-based model is only as powerful as the data used to feed & calibrate it.

In conclusion, the use of the NASA TRL framework in conjunction with test rigs, is essential for the successful development of new technologies, products, and systems. At AllWaves, we use both. Thereby we improve product quality, reduce development costs, enhance reliability, accelerate integration, and shorten our time-to-market.

To learn more about our wave pool product development, read further on our blog or follow us on social media.

Keep surfing!